Sectors

Mobility, Solutions for Automotive Suppliers

We supply our products to the majority of global automotive OEMs. Our steady growth in this business demonstrates our customers' confidence in a high quality product.

Our products offer optimal performance throughout the life of the vehicle.

Our solutions are efficient and modern, our concepts are innovative and this allows us to provide our customers with technical answers to environmental issues, a fundamental element of our thinking and that of our national and international customers.

WATERTIGHT COMPLEX SYSTEMS

The demands for complex waterproof systems in the mobility sector are numerous.

We manage all the manufacturing steps in our factories, from the co-development of the product, to the design of the production means, to the plastic injection molding of complex parts.

Our solutions are proven, we practice an autonomous and systematic control that guarantees the quality of our products. We use several types of technologies in order to ensure the tightness (pressurization, vacuum).

Hydraulic tanks

Brake fluid, power steering and fuel venting type tanks are the products developed by Microtechnic in the field of complex sealed systems in the automotive sector.

Gasoline / Diesel filling heads

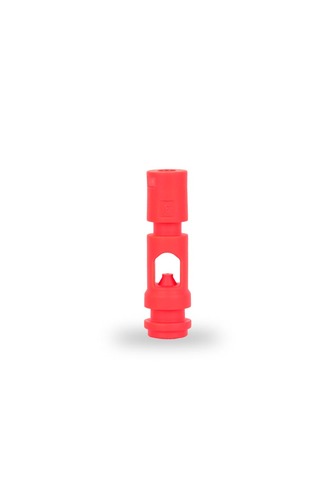

We are also engaged in the development and production of the necessary sealing functions for fuel tank filling.

From a unique system for proper detection of the MFI type filler nozzle, through the management of ICV (Inlet Check Valve) openings and closings to manage fuel flows, to the tank vent valve (OPR) to provide an automatic closing function in case of tank overturning or to allow gas to escape to the outside atmosphere in case of tank overpressure, our production units and machinery allow us to manufacture any kind of product in this particular field.

Caps

We also offer the ability to manufacture any type of caps, such as brake fluid or power steering reservoir caps.

SCR (Selective Catalytic Reduction) products

We also manufacture SCR products, which convert nitrogen oxides (NOx) into water and nitrogen without the oxides through an active emission control technology that injects a liquid reducing agent via a special catalyst into the exhaust stream of a diesel engine.

DRIVING ASSISTANCE

Driving assistance systems increase the safety and comfort of users on the road and thereby improve a driver's responsiveness by increasing his or her alertness.

Whether it is brackets for radar, e-mobility connectors such as battery charging connectors or components for car antennas, the products we design are made using robotic processes to ensure the architecture of the part meets our customers' specifications.

Thanks to our broad technological positioning and our presence on the international market, we can offer our customers key solutions.

Our components use fundamental technologies that enable intelligent systems to provide maximum safety for drivers.

We work with a combination of plastic and metal to design high performance connectivity systems that meet all the objectives required for driver assistance, all in full compliance with the most stringent regulations.

We can meet different types of needs and adapt them perfectly to all your projects.

PERSONAL SAFETY

Personal safety in the automotive sector is a fundamental element.

Each element participating in the improvement of the safety must be realized in the strict respect of the standards and must answer a precise schedule of conditions.

We work on the realization of several elements such as the mechanisms of seat or those of the headrests...

The realization of safety parts in the automotive industry requires a high level of mastery of plastic injection manufacturing processes.

Whatever your requirements in the automotive sector, we produce all types of safety parts.

We provide complete high-precision functions and have a real know-how in the architecture of mechanisms in several areas of the vehicle, so we are able to produce many parts necessary for the optimization of safety in the automotive sector.

Our know-how is the co-design and manufacturing in direct collaboration with our customers' design offices, offering a triple advantage: price, cost and technical solution.

Present us your needs, we will present you our possibilities of intervention.

MOTION TRANSMISSION

Plastic transformation allows new solutions (weight, resistance, sound, etc.) in your systems, especially in the automotive sector.

Microtechnic has been working for decades on the transition to alternative technologies and has acquired an in-depth knowledge of the internal workings of motion drives.

We provide new plastic solutions through a global approach to the business, we carry out all phases of the process to provide a comprehensive offer and total control of the process.

In terms of motion transmission in the automotive sector, we are able to produce all types of parts such as pinions, gears, screws... but also engine covers.

We work with multi-cavity molds whose immense precision allows us to produce extremely complex parts.

Our multi-cavity production line is fully robotized, ensuring high-level performance.